About Us

Print finishing equipment specialists

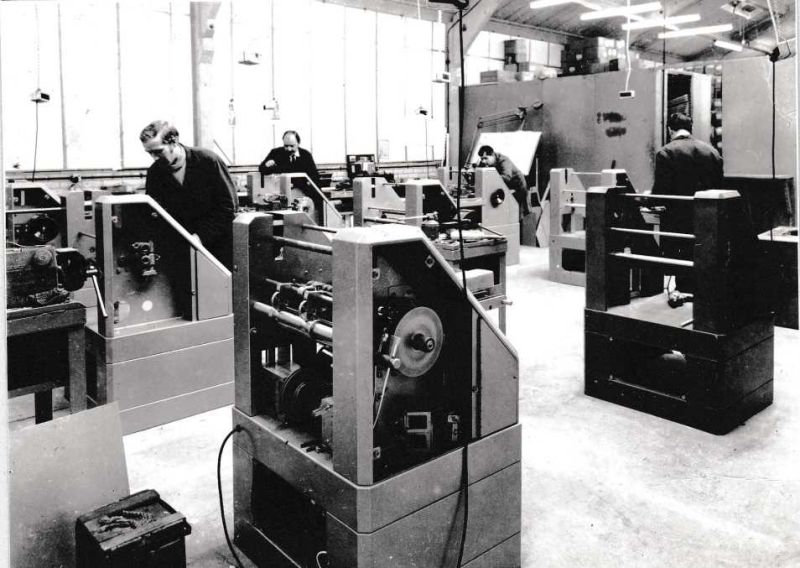

Rollem – The story behind our name

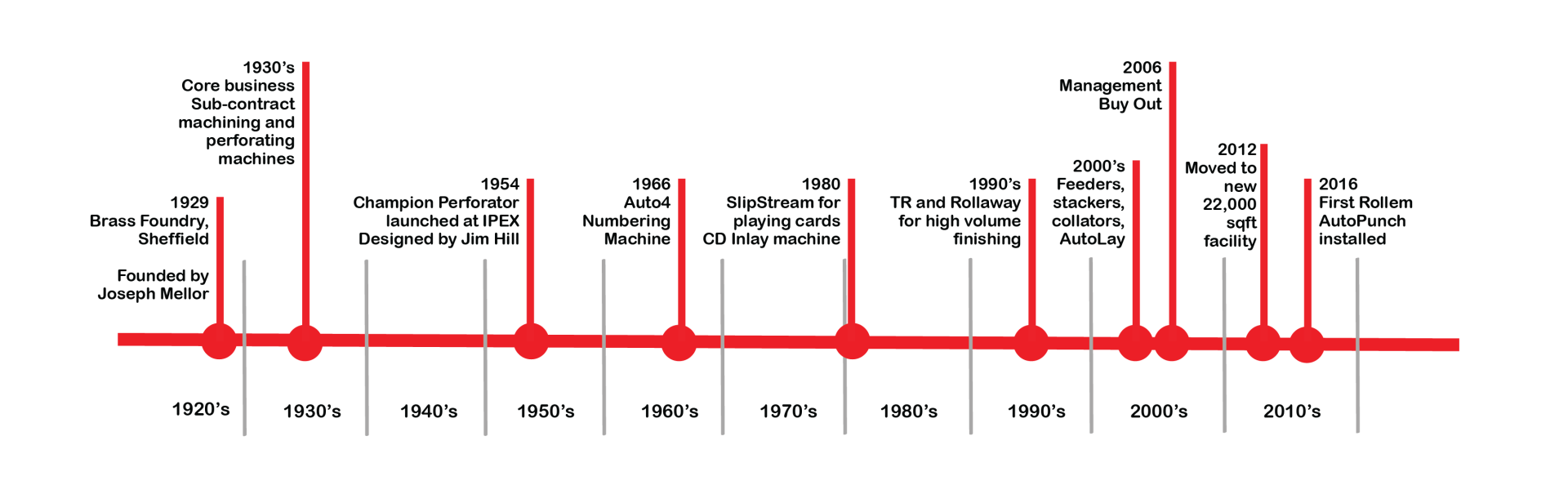

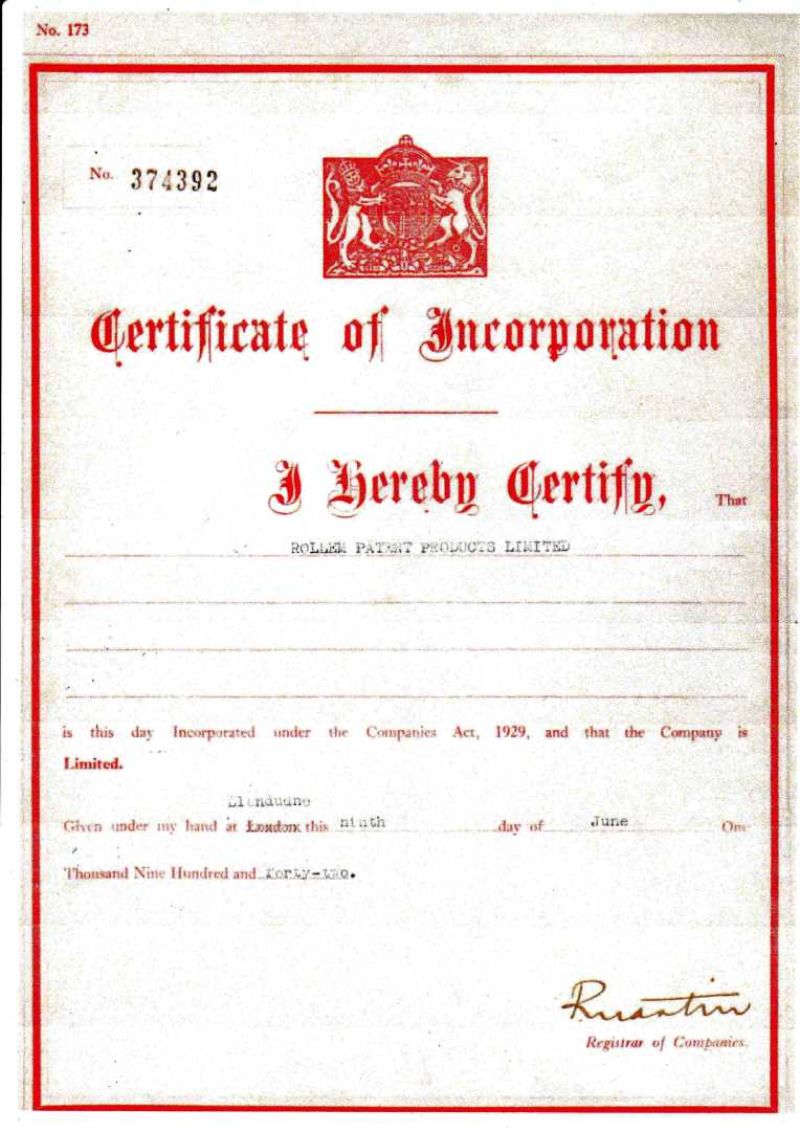

In 1929, our company’s founder Joseph Mellor set up a general engineering firm in Sheffield, Yorkshire. With the innovative approach that was to become a hallmark of his success, Mellor reversed his surname and christened his new venture ‘Rollem’. The company went from strength to strength, soon developing an international reputation as leading print finishing equipment suppliers.

Global success

We draw on nearly 90 years’ experience to create innovative, bespoke solutions for printers around the world. We export 85% of our production, including 50% to the demanding US market.

Today Rollem is a byword for quality, productivity and reliability in print finishing machines. Indeed, the Rollem name worldwide is so synonymous with first class finishing that it’s widely used as a generic name, just like the Hoover brand. In the international language of finishing, the verb ‘to Rollem’, as in ‘to Rollem a piece of print’, means to finish a job accurately, quickly and cost-effectively.

Print finishers’ online equipment

Finishing digital printing is an increasingly large part of our business, but whatever your print challenge we can help you finish it. Playing cards, business cards, trading cards, game cards, greetings cards, post cards, mailers, photo products, leaflets, labels, calendars, invoices and brochures – whatever print you’re looking to finish, look to Rollem.

Productivity

Our industry-leading systems combine exceptional productivity—slitting/trimming/perforating/creasing up to 15,000 A4 sheets an hour—with ultimate accuracy, on stocks from lightweight paper to plastic.

Our speedy floor to floor solutions can reduce manning levels up to 75%

All Rollem solutions are floor to floor, processing each sheet individually in a single pass. Install a Rollem solution and you can do away with the time-consuming process of finishing jobs batch by batch on separate machines with separate operators. When a job arrives, you can run and ship it in a single operation, efficiently converting sheets into deliveries and invoices into cash. A Rollem solution not only speeds turnaround and enhances productivity, it also delivers instant staffing savings.

The widest range of print finishing operations

From scoring, perforating, mircroperforating, creasing, slitting, trimming, guillotining, semi-slitting, collating, die cutting, rotary die cutting, punching, die punching and numbering.

The finest tolerances

Rollem machines regularly surpass the +/- .001” Las Vegas casinos demand on playing card decks and the +/- 0.2mm essential for CD inlays. Our reputation for accuracy is recognised too by the security printing sector.

Higher throughput and accuracy

Many Rollem solutions incorporate rotary-wheel technology to deliver higher throughput and accuracy than platen or fixed-knife machines. Our Research and Development department has even developed a rotary solution to slitting, perforating or scoring sheets up to 1.5m.

Unparalleled flexibility

Our machines are so flexible, you can set up a job in minutes. Set up is so fast because slitting, creasing and perforating tools on Rollem machines can be re-used, so you don’t have to create a new fixture for each job. Equally important, you can adjust individual tools – to fractions of a millimetre – in an instant. So, you can move a perforation line in next to no time.

To discuss your print finishing requirements please contact Andy Longston on +44 (0) 1226 745476 or [email protected]