Shelf Edge Labels

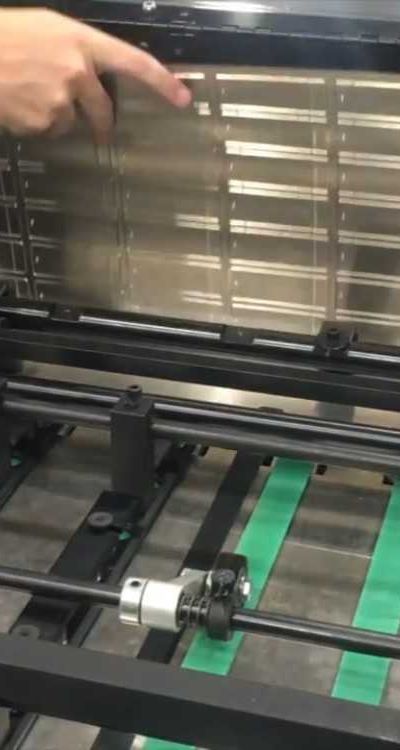

The Rollem system has reduced our production time and costs with a single operator, single pass system which cuts and collates the shelf edge labels ready for use by our customer. Excellent technical knowledge and customer service from the team at Rollem.

Print finishing of shelf edge labels has previously been a time consuming and labour intensive process with guillotines and multiple operators hand collating.

Sizes that can be run through the Rollem system can range from digitally printed SRA3 through to offset litho printed B1 sheets.

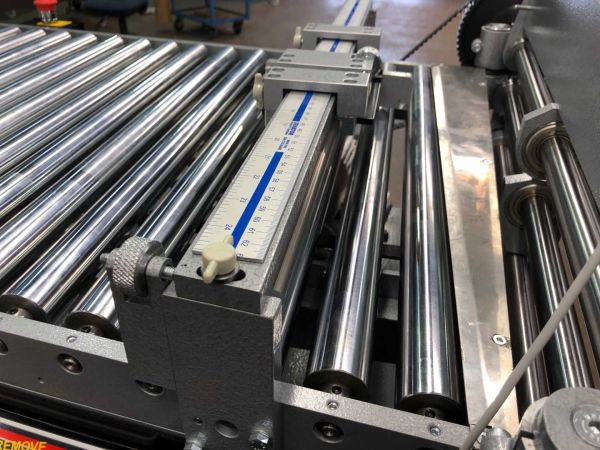

The Rollem JetStream can handle sheet weights ranging from 60gsm to 700gsm.

Depending on application and sheet size the Rollem machines can run up to 4,000sph, increasing the rate of production and decreasing your need for downtime between processes.

Batch labels can be collated in the order that they are then required in store making it more efficient for the end user.

To discuss your print finishing requirements please contact Andy Longston on +44 (0) 1226 745476 or [email protected]